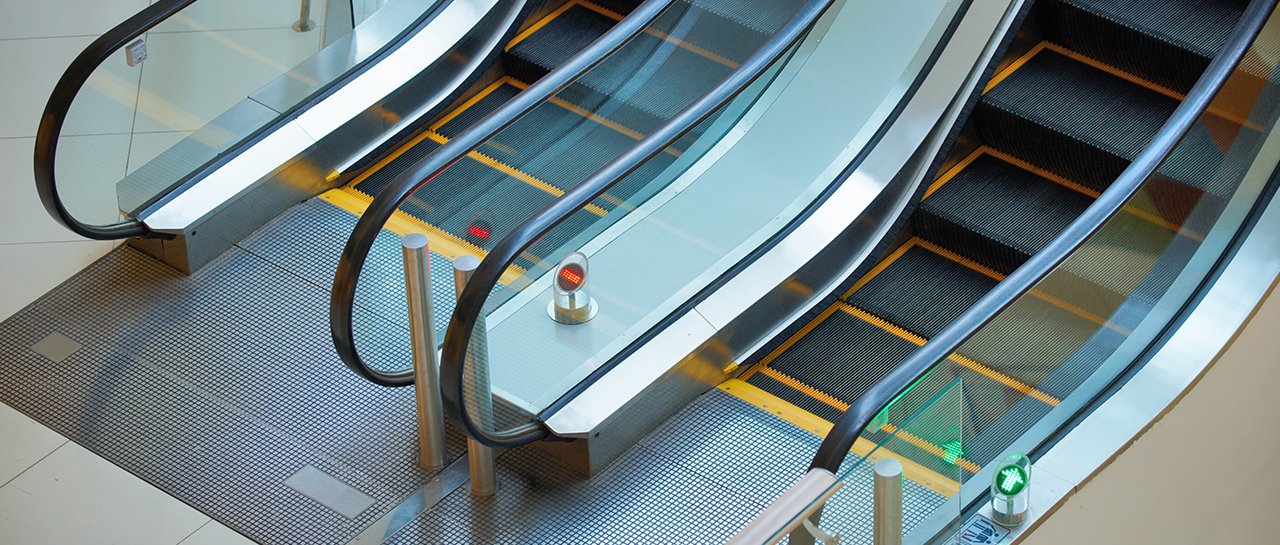

Article 18- Escalator Covering Requirements

Requirements to Consider for Escalator Covering

In this article, we intend to explain the escalator covering and their standard safety requirements and limitations in detail which must be considered by the manufacturers and project owners to eliminate the potential hazards and lead to a better appearance of the escalators.

Escalator coverings are essential components for escalators and moving walks. When designing an escalator or a moving walk, the manufacturers should also pay attention to the appearance of the escalator or moving walk along with the safety requirements. The escalator covering is mostly made of stainless steel sheets with different grades proportionate to the project requirements which provide an appropriate view, ease cleaning, and increase the durability of the covers. The balustrades (Solid Type), truss, deckings, and floor plates at landings are covered with these stainless steel cladding sheets. Covering escalator components properly leads to better protection of internal spaces against water, snow, dust and etc. from the surroundings. In addition, covering the escalators moving components, are effective in preventing escalator-related accidents arising from passengers being in contact with them.

The outside surface of the truss must be covered with appropriate panels called “Outside Cladding”. In indoor escalators and moving walks which are installed in commercial centers or where their appearance is important, we can use various materials for covering such as different kinds of stainless steel sheets, glass, composite sheets, or other materials based on customer taste.

Standard Requirements for Escalator Coverings

According to the standard EN 115-1:2017, all the mechanical moving parts must be enclosed by walls or Imperforated panels (without any gaps or spaces). This is not applicable for ventilation apertures, steps, and the part of the handrail which is designed for passenger use. To design the escalator covering, the standard has specific guidelines that are useful and practical and they have to be considered. These guidelines are as below:

- Any gaps or openings on the covers, close to moving parts with the risk of contact must be less than 4 millimeters.

- Exterior panels must withstand a force of 250 N at all points at the right angles in a 2500 mm2 round or square area without breakage.

- The fixings must be able to carry a minimum of twice the dead weight of the panels.

- The covers of mechanically moving parts can be removed in restricted areas accessible to authorized personnel only, where there is no threat to the public.

- Ventilation apertures must be designed and arranged in compliance with EN ISO 13857:2008 standard. However, a straight rigid rod 10 millimeters in diameter must not pass through enclosures of ventilation aperture to touch the moving parts.

- Safety devices must be provided for any exterior panels that can be opened for cleaning or maintenance purposes.

Inspection Covers Requirements

Some of the escalator covers such as balustrade, outside cladding, and floor plate are considered as inspection covers that have their own specific requirements in addition to the above-mentioned points. It should be noted that the parts of the balustrade such as deckings and skirt panels that can be opened for maintenance purposes are not counted as inspection covers. According to EN 115-1:2017 some of the requirements for the inspection covers are as below:

- Inspection coverts must be imperforated panels.

- Inspection covers must be provided with safety contact.

- When the inspection covers have two parts or more, one safety device must be provided for the first panel and other panels must be designed in a way that they cannot be opened or removed before the first panel is opened. If all of them can be opened in any order, we must install a safety device for each panel.

- Inspection covers must be opened only by keys or a suitable tool.

- If the authorized person enters a space where the inspection cover is considered as its door, the inspection cover must be opened from the inside and no locks shall be considered. ( e.g. Floor plate of machine room spaces).